Overview of the manufacturing process from raw materials to finished product

MES (Manufacturing Execution System) is a software system that monitors, manages, documents, and checks the manufacturing process from raw materials to the completion of the finished product. It acts as a bridge between the company’s management systems (e.g. ERP) and manufacturing activities.

MES is essential for ensuring:

Key functions of MES

How can MES be implemented in manufacturing processes?

Modern digital technologies

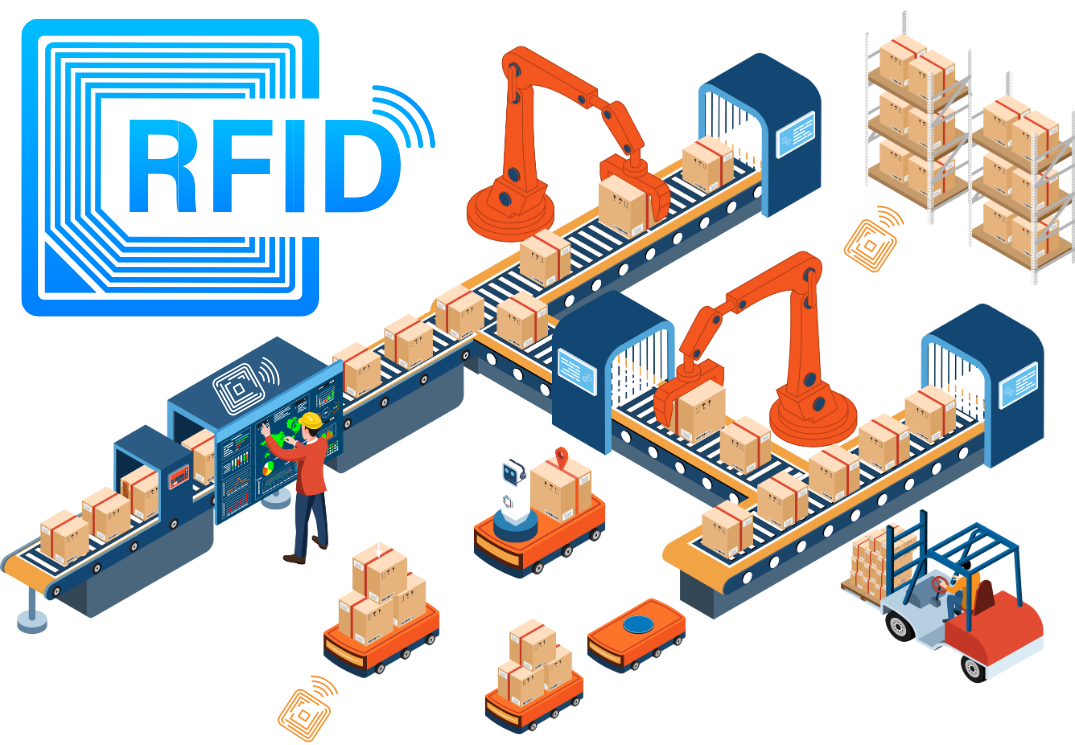

Machine vision and RFID make real-time monitoring of manufacturing possible

The capability of RFID tags for remote readability and information storage, combined with machine vision technology’s ability to recognise and interpret objects, images, text, and faces, enables us to provide an accurate and reliable MES solution.

Advantages of implementing MES (competitive advantages)

Real-time monitoring of manufacturing and quality is a significant step towards digitalisation and increased profitability.

The MES system is integrated with enterprise management systems

MES can be integrated with other systems such as ERP (Enterprice Resource Planning), PLM (Product Lifecycle Management) ja SCADA (Supervisory Control and Data Acquisition) providing a comprehensive overview of the entire manufacturing process.

What are the benefits of implementing an MES system?

Industrial applications of MES

Which companies benefit from MES?

MES is used in various industries, including automotive, aviation, electronics, pharmaceuticals, food and beverage, and more. In every industry, MES is tailored to meet specific manufacturing requirements, ensuring that the system supports the unique needs of the manufacturing environment.

Implementing MES gives manufacturers a competitive edge by offering better control, visibility, and optimisation of manufacturing processes.

Use case

RFID manufacturing solution for Aru Group

Aru Group has implemented a manufacturing monitoring system based on standardised RFID technology. RFID technology enables to digitalise various work processes and stages in both manufacturing and assembly.

Integrating a suitable solution for Aru Group helps them monitor and manage manufacturing activities in real time.

Improved information exchange

Clearer work organisation

Better planning and smoother workflow

Information for operational changes

Overview of the production history

To find out the causes of defects

Data for statistics and reports

Visualisable data

What problem did we solve?

A better overview of the current state and manufacturing processes was necessary. Some information was only available on paper, causing delays when searching for a part’s manufacturing history, for example. There was no quick overview of parts that had not been produced for some reason, causing delays. A significant amount of information noise in manufacturing and assembly led to the simultaneous transmission of information to everyone, sometimes making it difficult to understand who should act on the information and how.

Solution:

The manufacturing solution, digitalised with RFID technology, facilitates production planning and enables operational changes if needed. RFID also allows you to collect important data for compiling statistics and reports, which can be visualised and used to make operational and strategic decisions.

Contact us

We offer a comprehensive MES manufacturing solution – starting with consultation and ending with integration into existing systems.

Reg.no. 11716262

VAT identifier: EE101332363