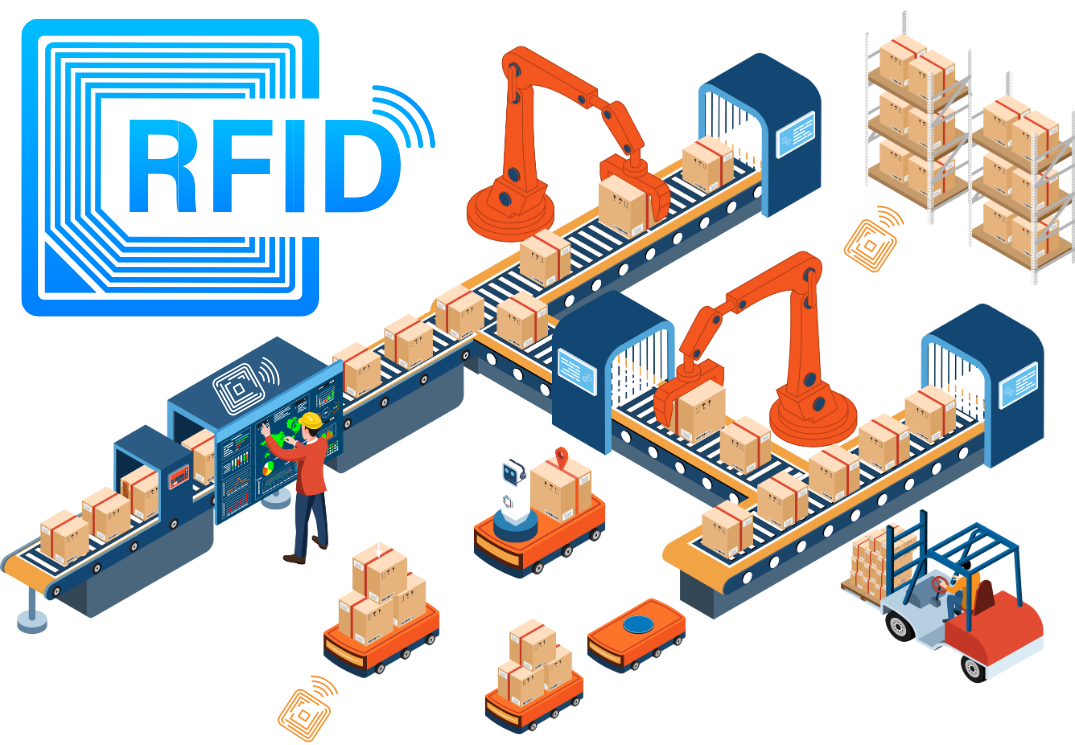

RFID technology is based on the propagation of radio waves

RFID tags (stickers) include a microchip and an antenna. Thanks to their construction, they can store information and transmit it to the reader. Because this technology does not require direct visibility between the tag and the reader, it is possible to identify many goods and objects at once. For example, all the goods on a pallet or the entire inventory in a room can be identified.

RFID allows real-time monitoring of fixed assets and supplies

Hospitals, care homes, manufacturing companies, maintenance companies, warehouses, offices, shops, and many other businesses have a large amount of inventory that needs to be tracked.

Using RFID technology, we automate asset tracking process and digitalise the data flow.

Examples of RFID applications

How does RFID technology work?

Use case

RFID manufacturing solution for Aru Group

Aru Group has implemented a manufacturing monitoring system based on standardised RFID technology. RFID technology enables to digitalise various work processes and stages in both manufacturing and assembly.

Integrating a suitable solution for Aru Group helps them monitor and manage manufacturing activities in real time.

Improved communication and reduced information noise

Clearer work organisation

Better planning and streamlined workflow

Information for operational changes

Overview of part production history

To identify the causes of defects

Data for statistics and reports

Visualisable data

What problem did we solve?

A better overview of the current state and manufacturing processes was necessary. Some information was only available on paper, causing delays when searching for a part’s manufacturing history, for example. There was no quick overview of parts that had not been produced for some reason, causing delays. A significant amount of information noise in manufacturing and assembly led to the simultaneous transmission of information to everyone, sometimes making it difficult to understand who should act on the information and how.

Solution:

The manufacturing solution, digitalised with RFID technology, facilitates production planning and enables operational changes if needed. RFID also allows you to collect important data for compiling statistics and reports, which can be visualised and used to make operational and strategic decisions.

Contact us

We create comprehensive solutions for production management, quality monitoring, and tracking of goods and inventory using RFID technology.

Reg.no. 11716262

VAT identifier: EE101332363